Introduction to Laser Cleaning and Refinishing

Laser cleaning and refinishing technologies are revolutionizing industries by providing a highly effective, precise, and eco-friendly solution for removing contaminants, rust, paint, and coatings from various surfaces. This cutting-edge method utilizes laser beams to vaporize unwanted materials without damaging the underlying substrate, making it an unparalleled choice for a wide range of applications.

Lasers Clean Fast, Precisely and Sustainably Without Detergents or Abrasives

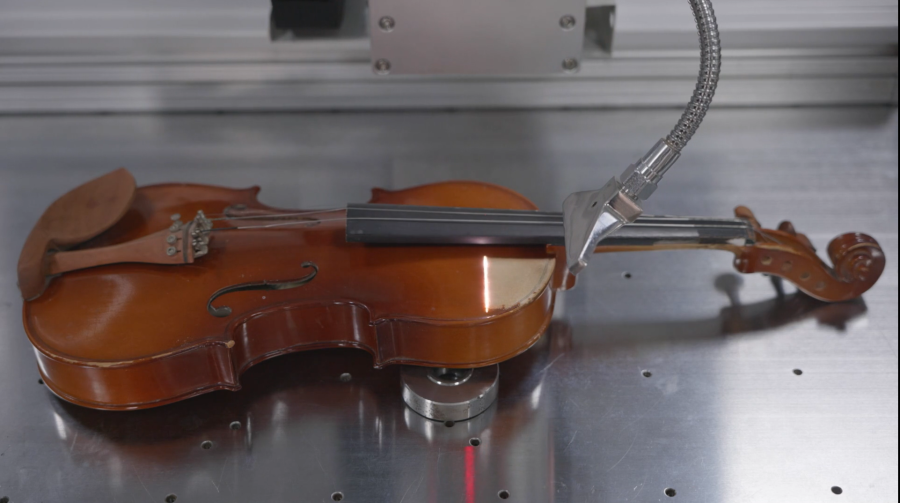

Wood and other Materials

A laser cleaning machine directs a highly focused beam of light onto the stained area and the laser beam is adjusted to target the specific color or material of the stain, causing it to heat up rapidly with intense heat causes the stain to vaporize or evaporate, effectively breaking its bond with the wood leaving the wood underneath untouched. It can be used on various types of wood and stains, as well as for removing paint, varnish, and other finishes.

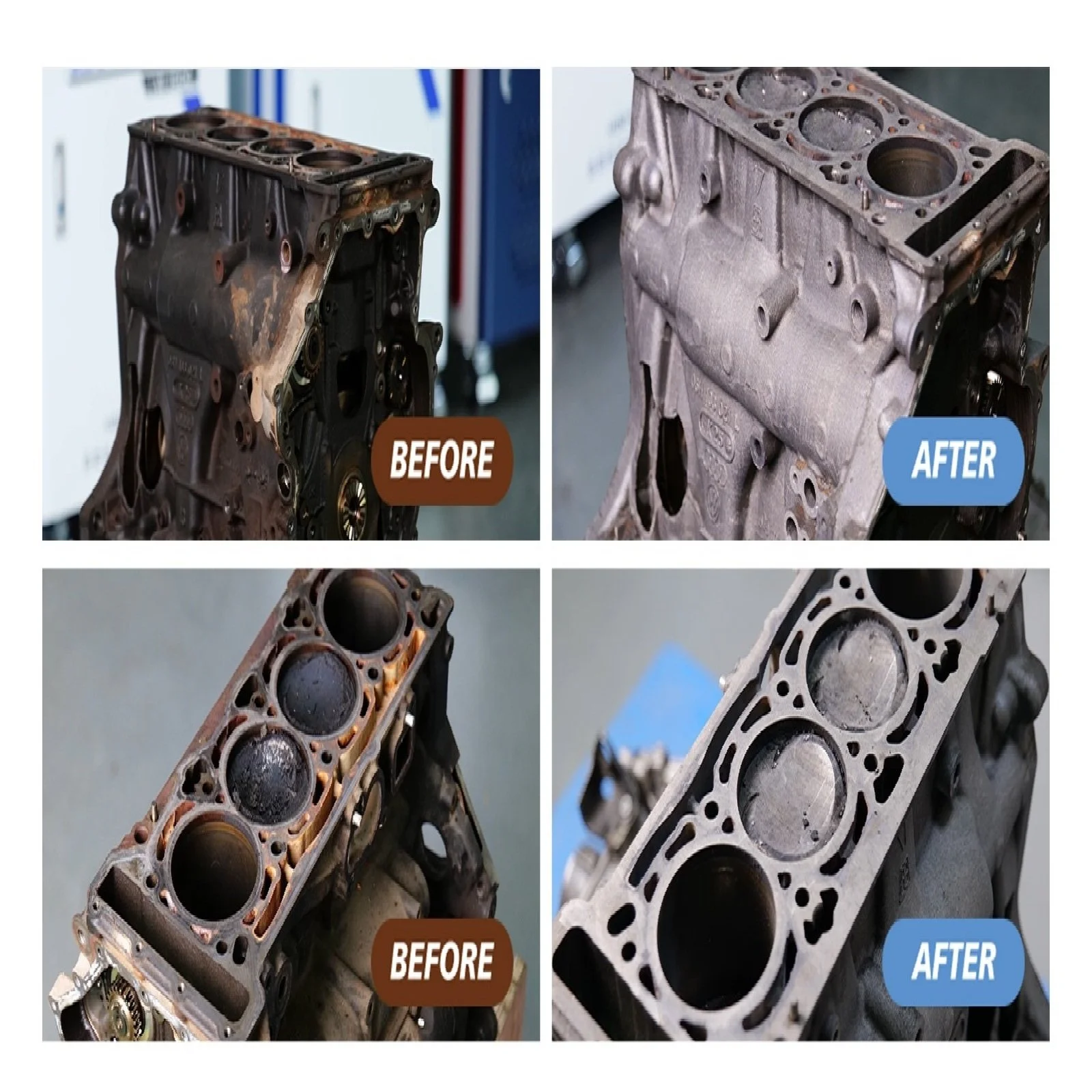

Oil And Grease

Laser cleaning removes oil and grease from engines by using focused laser beams to vaporize the contaminants, effectively lifting them from the surface. This non-contact method utilizes the high energy and density of laser light to break down the molecular bonds of oil and grease, causing them to turn into vapor and detach from the metal. The process is precise, minimizing damage to the underlying engine components.

Restaurant Cooking Equipment

Laser cleaning removes oil and grease from restaurant cooking equipment Non-contact method, meaning it doesn't require physical scrubbing or the use of harsh chemicals, reducing the risk of damage to the equipment and the beam can be precisely controlled, allowing for targeted cleaning of specific areas and avoiding damage to surrounding surfaces.